Products

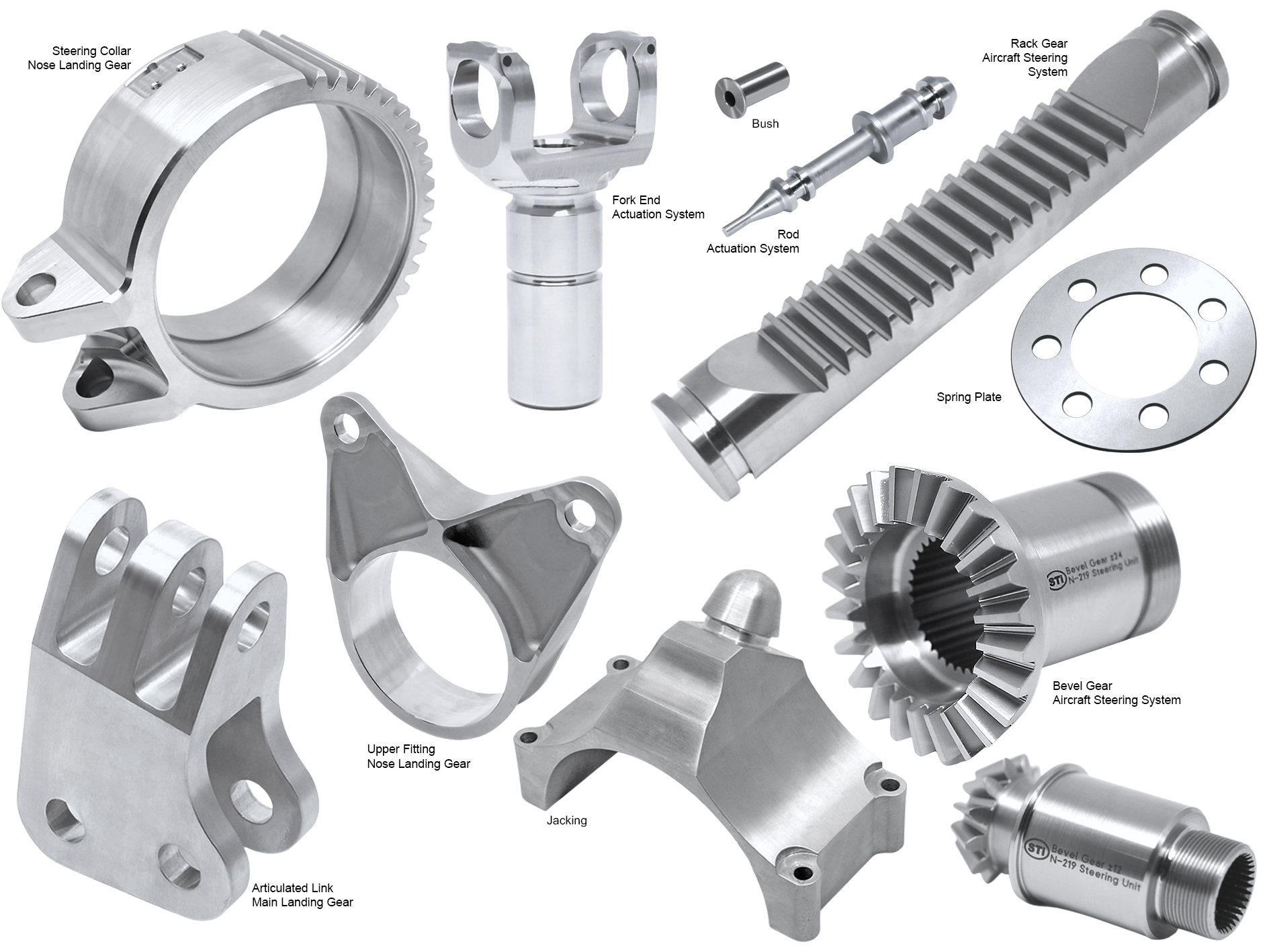

Aerospace Component

Aerospace Component

STi is an AS9100D certified company. We manufacture Aerospace Component based on Customer’s drawing and requirement. Our unique capability allows for extensive in-house development of Workholding system, Special Cutting Tool, Inspection Gage and Fine Machining of Aerospace Component.

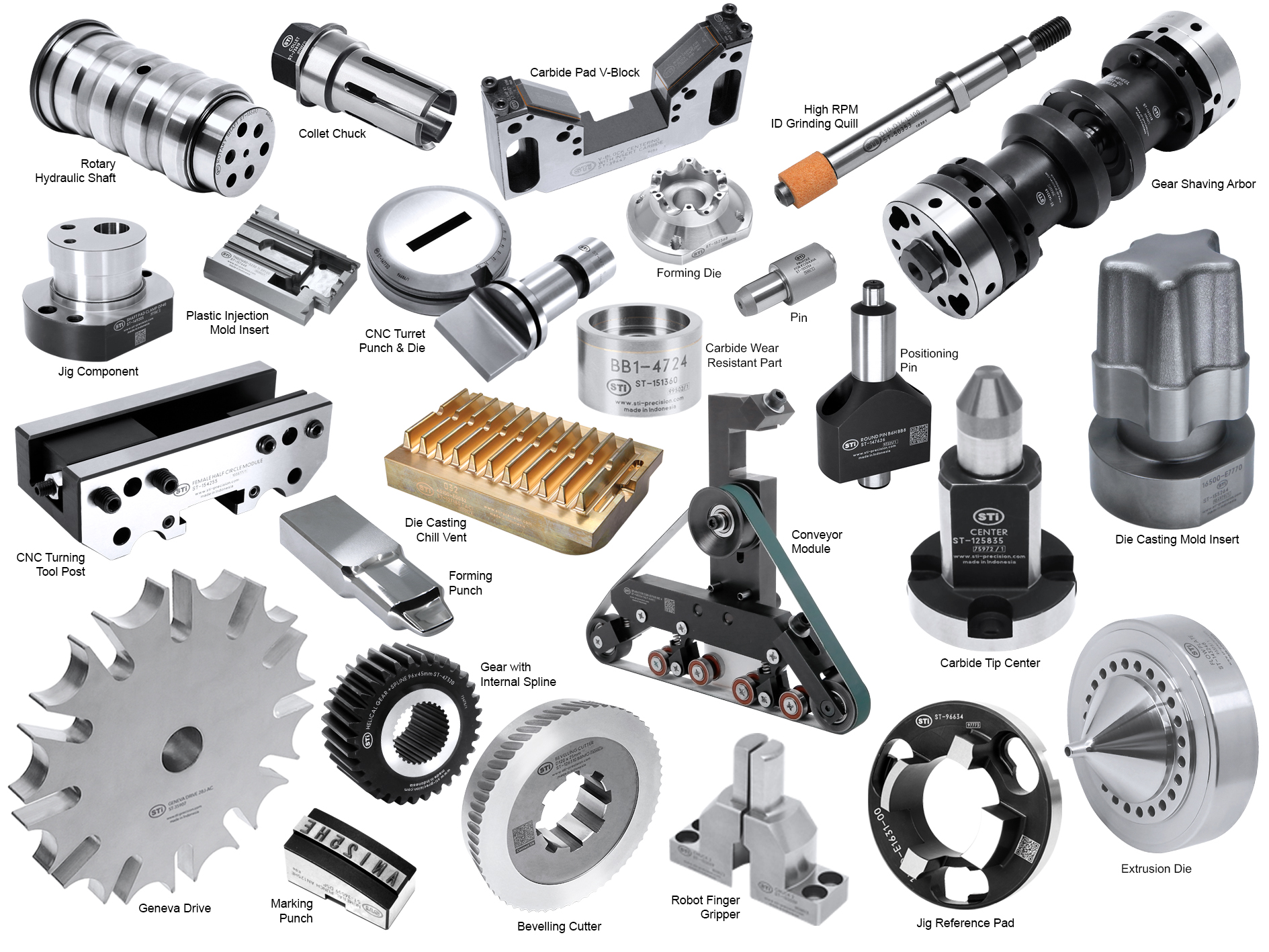

Industrial Component

Industrial Component

STi’s key product since 1979. We manufacture Industrial Components for diverse industries, machines and materials. We machine soft polymer, non-ferrous, ferrous, hard metal to ultra-hard materials with state-of the art machining, measuring and reverse engineering facilities. Our extensive know-how in tolerancing and machining allows for longer component service life for our customers.

Special Cutting Tool

Special Cutting Tool

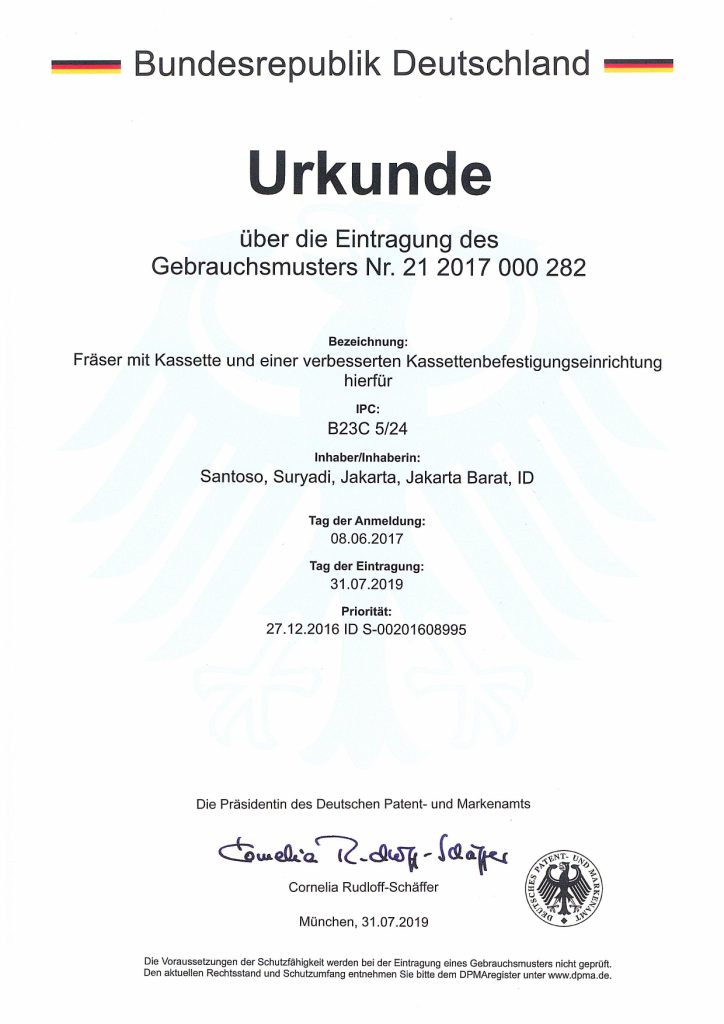

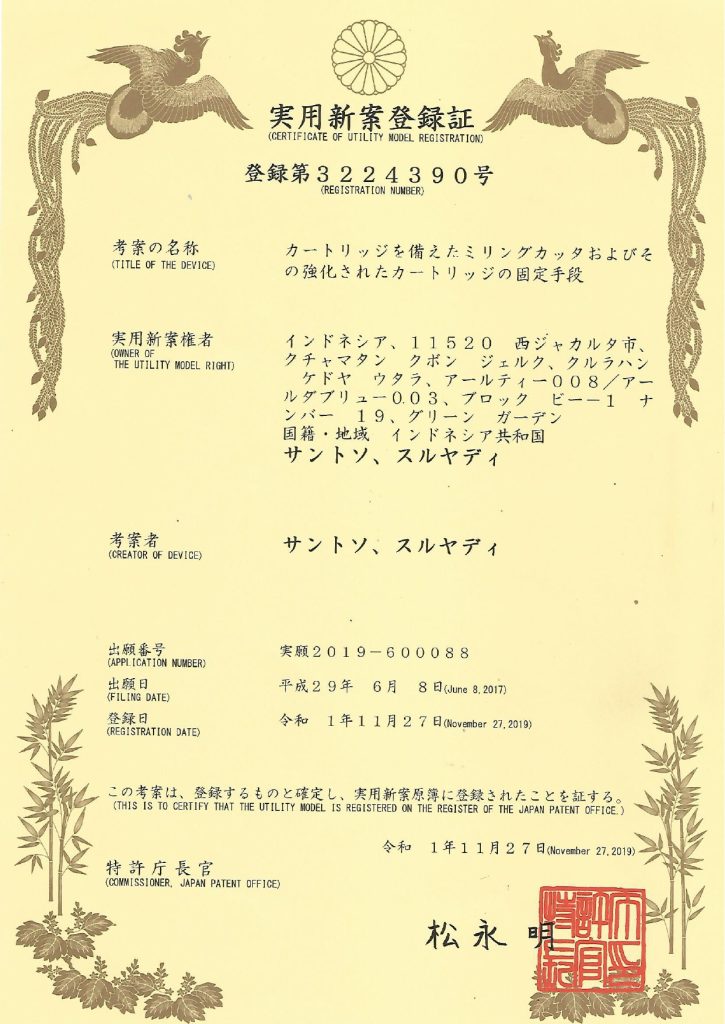

STi is known for innovative design, utmost precision and the finest quality of our Special Cutting Tool for the metalworking industries. We manufacture Special Tool Holder, Special Carbide Inserts, PCD and PCBN Tools for the Aerospace, Automotive and Consumer goods industries. STi holds international patent for clamping system design in PCD tool. Our fine made tools allows for lower cost per-piece, consistently.

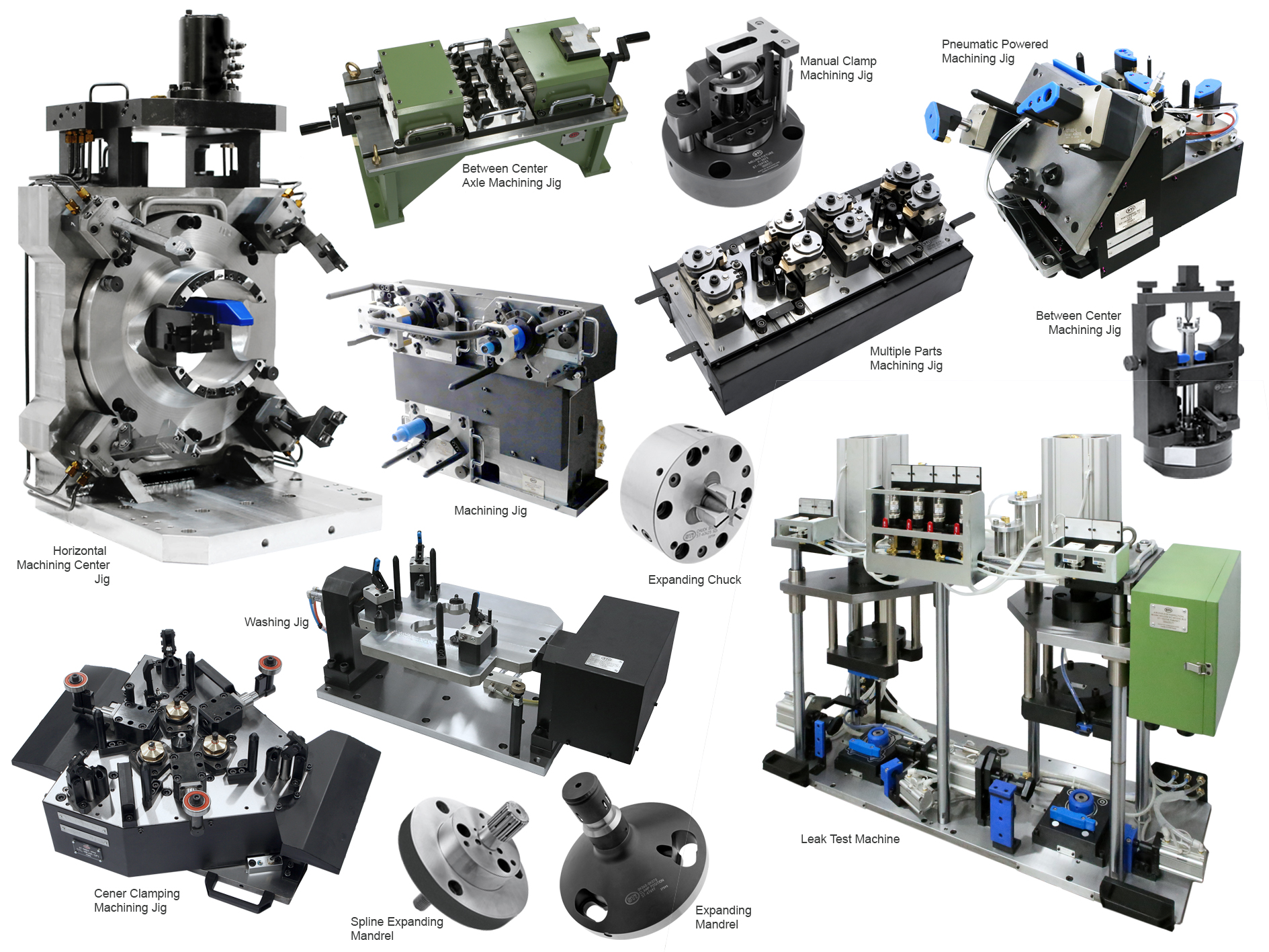

Workholding

Workholding

STi design and manufacture various kinds of Workholding system such as Jigs & Fixture, Chuck, Collet, Center, Arbor and Mandrel for the Aerospace, Automotive and Consumer goods industries.

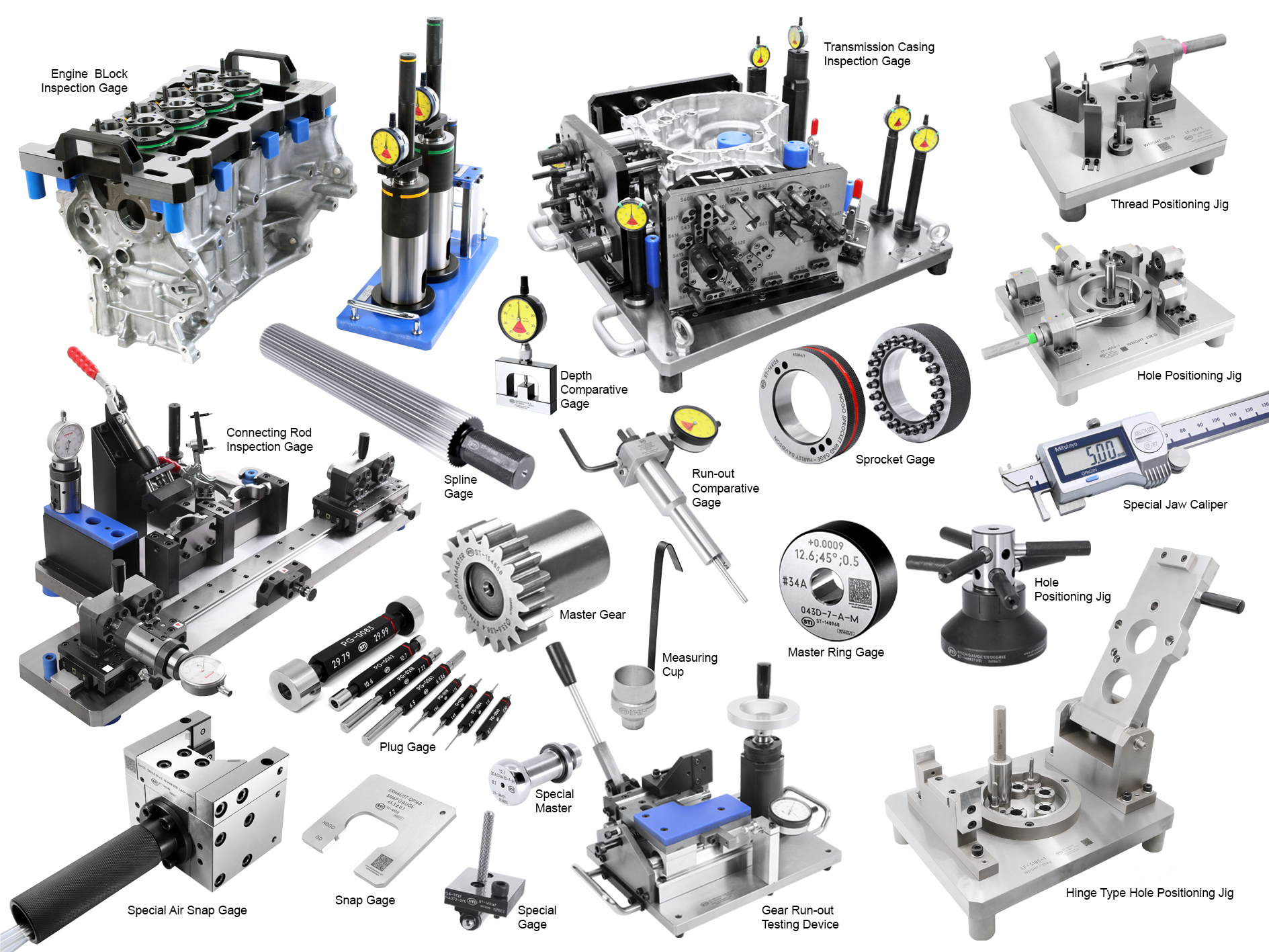

INSPECTION GAGE

Inspection Gage

STi design and manufacture various Inspection Gage from Hand Gage, Comparative Gage, Master, Thread Gage to complex Positioning Gage for the Aerospace, Automotive and Consumer goods industries. Our Calibration Laboratory is ISO17025 certified – ILAC MRA. In-house cryogenic facility along with subzero precision capability in steel and tungsten carbide established ourselves as top gage manufacturer in the country.

OEM

OEM

Our unique capability for full in-house design, development and manufacturing of supporting equipment along with producing the OEM product allows STi to provide utmost flexibility in fulfilling customer’s requirements. Our OEM products are manufactured for the Aerospace, Automotive and Consumer Goods industries. We have long experience in machining of non-ferrous and ferrous materials in large quantity.

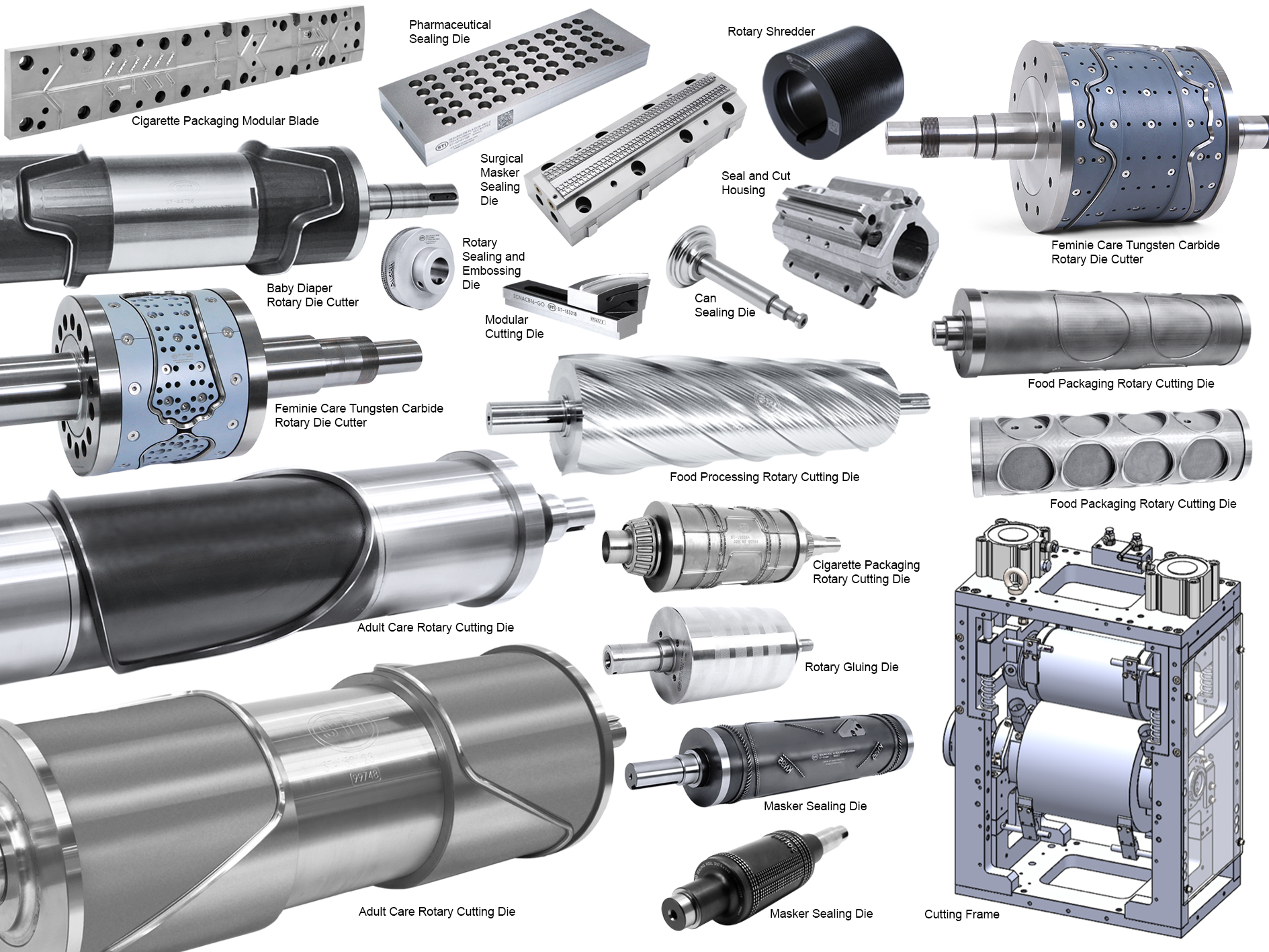

Rotary Die and Tooling

Rotary Die and Tooling

STi has the capability to produce Tungsten Carbide as well as Hardened Steel Rotary Cutting Die, Sealing Die and Embossing Die for the Consumer Goods industries. Furthermore, Rotary Die Modular Frame for the transfer line machines are produced in-house.

SHEET METAL FABRICATION

Sheet Metal Fabrication

STi has a comprehensive facility for Sheet Metal Fabrication from Laser and Waterjet cutting, Bending, Welding, Painting as well as assembly to Mechanical Components. Our dedicated Sheet Metal Plant serves low volume high mix as well as high volume OEM requirements.

Services

Reconditioning of Carbide and Hardened Steel Rotary Die Cutter

Waterjet and Laser Cutting Service

Carbide, PCD and PCBN Cutting Tool Reconditioning

Calibration of Measuring Instrument and Inspection Gage

Facilities

Manufacturing Facilities and

Capabilities

1. Conventional Machining

2. Non-Conventional Machining

3. Special Process

4. Unique Capabilities

MANUFACTURING FACILITIES AND CAPABILITIES

Conventional Machining:

3 to 4 axis CNC Jig Class Machining Center

3 tp 6 axis CNC Machining Center

4 to 6 axis CNC Turn-Mill Center

5 to 6 axis CNC Grinding Center

Jig Grinding Machine

CNC and Manual Cylindrical Grinding Machine

Surface and Form Grinding Machine

Gear Hobbing Machine

Slotting Machine

Non-Conventional Machining:

CNC Wire EDM

4 axis CNC Ram EDM

EDM Drill

CNC Precision Waterjet Machining Center

4 axis CNC Laser cutting machine, with pipe cutting capability

Special Process:

Cryogenic / Subzero treatment machine

Heat treatment furnace

Aluminum anodizing

Nickel coating

Black oxide coating

TIG welding

MIG/MAG welding machine

Dedicated welding table and fixture

Robot welding machine

Vacuum brazing furnace

Induction brazing generator

Painting

Unique Capabilities:

STi is able to achieve 1 micron accuracy in size and geometric tolerance (subjected to size and shape

Assembly facility able for precision mechanical, pneumatic and hydraulic assembly.

Quality Control and

Reverse Engineering Facilities

1. Contact Measuring Machine and Instrument

2. Non-Contact Measuring Machine and Instrument

Quality Control and Reverse Engineering Facilities

Contact Measuring Machine and Instrument:

ULM with 0.1micron resolution

CNC multi-axis CMM

Portable - Measuring Arm CMM

CNC Roundness Measuring Machine

Contour Measuring Machine

Laser Measuring Machine

Linear Measuring Machine

Air Gage Tester

Rockwell C Hardness Tester

Brinell portable Hardness Tester

Surface Roughness Tester

Hand Measuring Instruments and Gage Blocks

Non-Contact Measuring Machine and Instrument:

CNC Vision Measuring Machine for Components

CNC Vision Measuring Machine for Cutting Tools

Stereo Microscope

Profile Projector

Measuring Scope

Cooperation

KURITA TECHNO CO., LTD.

NIPPON TUNGSTEN CO., LTD.

OSG USA, INC.

About Us

Our Story

Our humble beginning in 1979 started from Mr. Santoso’s dream to meet the growing demand in quality mechanical components for the domestic industries. CV. SANTOSO was established in the residence of the Santoso family in the city of Tangerang, suburb of the capital city, Jakarta in Indonesia.

Since the early years, we are recognized for the quality and value of our product. In order to ensure optimum control of manufacturing processes and quality, we manufacture our products in-house.

Over time, STi business and product line expand along with customer’s trust and support. We not only serve low volume high mix production, but also high volume mass production of mechanical components.

Thanks to our employees and customer’ support, we have grown to become a national leader in precision machining in Indonesia and expanding our market internationally.

Our list of esteemed clients along with the comprehensive machining expertise and the state-of-the-art facilities are confirmation of our commitment to our customers.

Our Motto

Your one stop shop for “Plug and Play” and long lasting product, because we understand the value of your MACHINE UPTIME.

Our Mission

We are the one stop shop for custom machining and fabrication needs. We build the best “plug and play” products and unique solutions, because we understand the value of your MACHINE UPTIME.

Our Vision

To enable our customers realizing the full potential of their production and to become the customer’s preferred choice in custom machining, fabrication and engineered product, globally.